Add to Cart

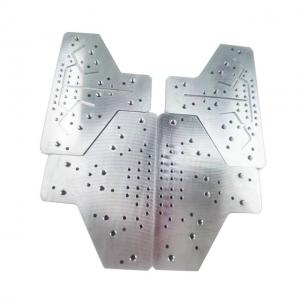

Aluminium Machined Parts 6061 7075 Aluminum Cnc Machining Parts Turning

Turning Metal Description:

Machinery: Turning metal is typically performed using a lathe machine, which securely holds the workpiece and rotates it while a cutting tool removes material. Modern CNC (Computer Numerical Control) lathes provide greater precision and automation, allowing for efficient and accurate turning operations.

Material Compatibility: Turning metal is suitable for a variety of materials, including metals like steel, aluminum, brass, titanium, and more. The process can handle both ferrous and non-ferrous metals, making it versatile for different applications.

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14,12L15,4140, 4340,Q235, Q345B, 20#, 45# etc |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc plating | Nickel plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder-coated |

| Polishing | Oxide black | Heat treatment | |

| Chroming | | Powder Coated |

Turning Metal Advantages:

We accept OEM and ODM projects with your authorization, allowing us to create custom components based on your specific requirements.

Our company is equipped with 4/5/6 axis machinery and staffed with senior engineers skilled in programming. This enables us to meet your needs for precise components.

We have dedicated teams for quality control (QC) and research and development (R&D). These teams work diligently to ensure high-quality products and continuous improvement in our processes.

Company Profile:

Shenzhen Hongsinn Precision Co., Ltd is a reputable company located in Shenzhen, China. We are known for our advanced equipment, cutting-edge manufacturing technology, and our commitment to delivering high-quality products with competitive pricing and on-time delivery.

Established in 2010, our company, Hongsinn, operates within a spacious facility spanning an area of 2000-3000 square meters. We specialize in the production of high-precision CNC machining parts, stamping parts, plastic injection parts, hardware, and mold parts.

With 13years of industry experience, we have amassed a fleet of 40-60 machines, the majority of which are imported from renowned manufacturers in the United States and Japan. Notable examples include the HAAS VF-2SS (5-axis) from the United States

We pride ourselves on our ISO9001:2015 and ISO13485:2016 certifications, which demonstrate our commitment to providing flexible solutions tailored to our customers' specific demands. our stringent quality control system ensures that all products undergo 100% inspection before they are shipped.

At Hongsinn, we place great emphasis on product quality, and our offerings find application in various industries such as aerospace, architecture, automotive, commercial, medical, optical, Our products enjoy a positive reception from clients across America, Germany, Asia, Europe, and other countries worldwide.

Our goal is to exceed customer expectations by delivering high-quality products, exceptional service, and a continuous drive for improvement. We welcome your inquiries and calls, and we are confident in our ability to serve as your reliable partner.