Add to Cart

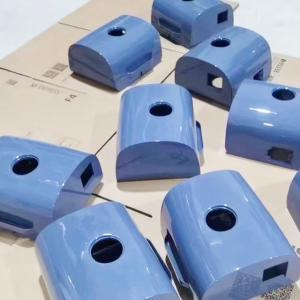

3D Printing Plastic Painting Anodizing Machined Part

SLA 3D Printing Service:

Our company provides SLA (Stereo Lithography Apparatus) 3D printing services, employing an ultraviolet (UV) laser to solidify light-sensitive resin layer by layer, resulting in precise 3D objects.

Material:

We utilize resin materials for SLA 3D printing, including options such as ABS-Like resin and Acrylic-Like resin. These materials possess exceptional properties for creating intricate structures and small components.

Applications:

SLA 3D printing excels in producing intricate designs and small, precise components with excellent surface finish. This manufacturing process enables the creation of complex geometries and fine details that can be challenging with other methods. Additionally, SLA-printed objects can be painted in a wide range of colors, offering further customization possibilities.

By leveraging SLA 3D printing technology and utilizing resin materials, we can transform your designs into tangible objects with remarkable accuracy, intricate details, and a smooth surface finish. Whether you require prototypes, functional parts, or intricate models, our SLA 3D printing service provides an ideal solution for producing high-quality, visually appealing objects with outstanding tolerance and surface finish.

FAQ:

1.Are you a manufacturer or a trading company?

We are a factory covering an area of 3000 square meters located in Guangdong, China.

2.How can I obtain a quotation?

Please provide detailed drawings (PDF/STEP/IGS/DWG...) with information on material, quantity, and surface treatment.

3.Can I receive a quotation without drawings?

Certainly, we would appreciate it if you could provide samples, pictures, or drafts with detailed dimensions for an accurate quotation.

4.Will my drawings be kept confidential?

Yes, we prioritize the protection of our customers' privacy regarding drawings. We are also open to signing a non-disclosure agreement (NDA) if required.

5.Can you provide samples before mass production?

Certainly, a sample fee will be required and will be refunded if mass production is confirmed.

6.What is the lead time?

Typically, it takes 1-2 weeks for samples and 3-4 weeks for mass production.

7.How do you ensure quality control?

We have a comprehensive quality control process that includes:

(1) Material inspection: Checking the material surface and approximate dimensions.

(2) Production first inspection: Ensuring critical dimensions are met during mass production.

(3) Sampling inspection: Checking the quality before sending the products to the warehouse.

(4) Pre-shipment inspection: Conducting a 100% inspection by QC assistants before shipment.

8.What actions will you take if we receive poor quality parts?

Please provide us with pictures, and our engineers will promptly find solutions and remake the parts for you.